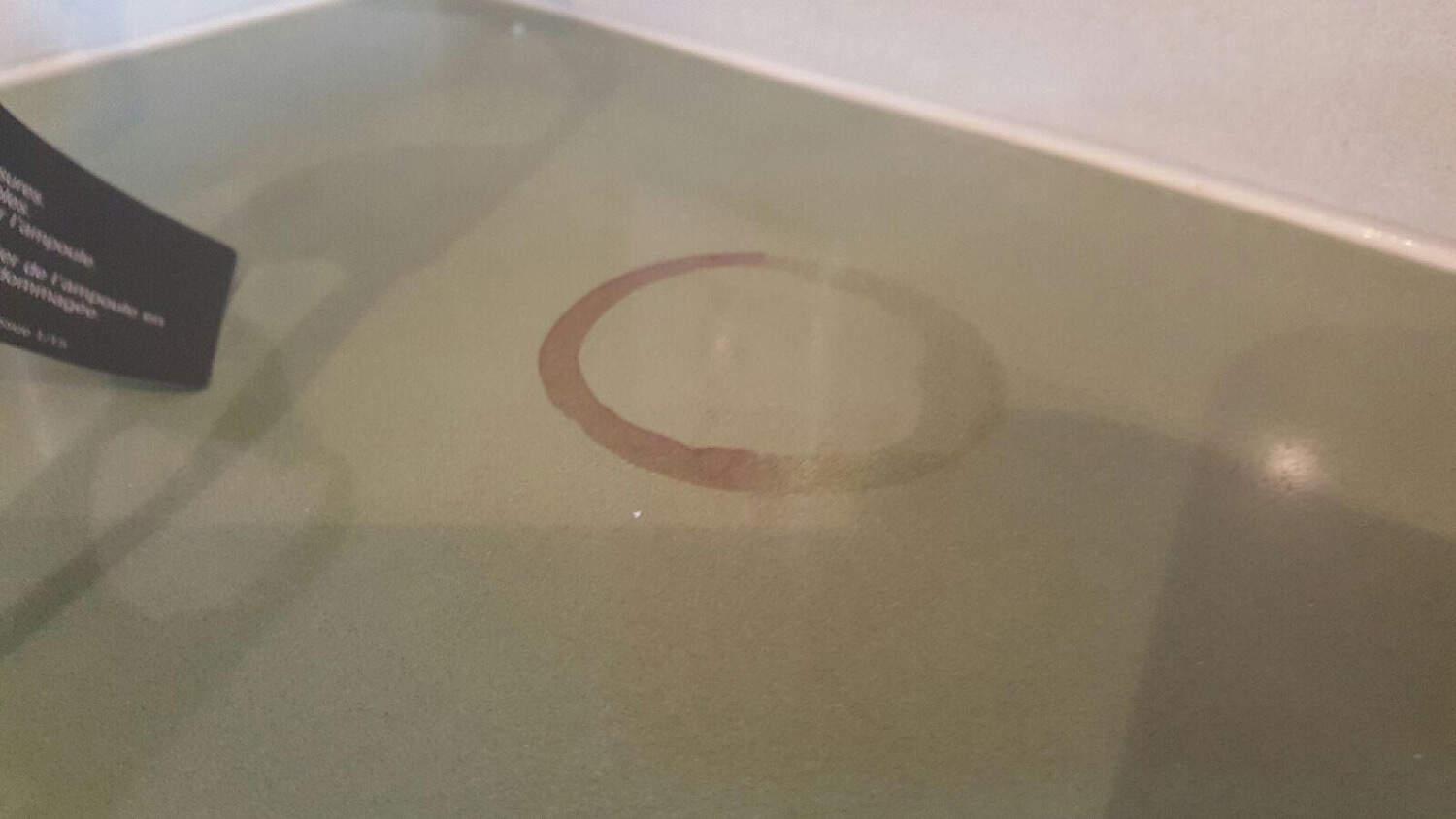

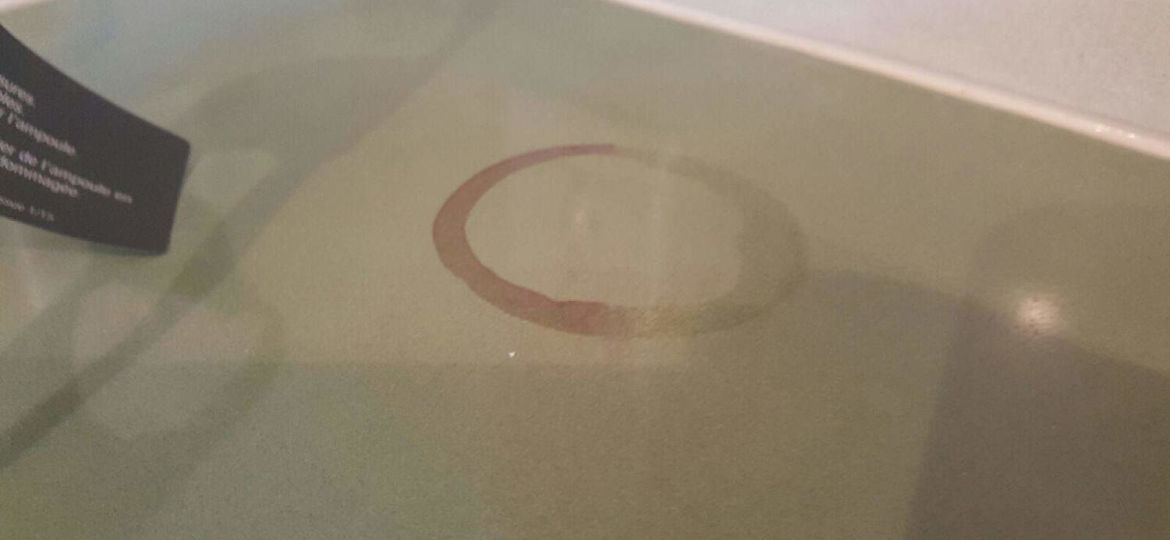

Here are the sequential results of a stain test performed in a client’s home on their concrete countertops by said client. We used red wine around the base of a glass, which is a very likely scenario. We left it on the countertop for a couple hours then lifted the glass and wiped half of the ring off. As you can see, after a short amount of time (I think the total duration was about 2 glasses of wine), the ‘stain’ was no more.

Today, I’m going to tell you a big hairy secret in the designer concrete world, which includes concrete countertops, concrete sinks, concrete furniture, and everything else we do here at Béton Studio. Are you ready for the secret?

Concrete Stains

I think I heard the collective gasp as the record skipped.

But there is a lot more to it than just that statement. Keep reading.

You see, concrete is a natural material. Just like any other natural material, concrete is porous and susceptible to staining. You wouldn’t expect untreated wood to resist darkening in the presence of, say, beet juice or wine.

Everyone has come to expect that white marble is going to show red wine stains, so much so that marble companies give a stain removing poultice away with the sale of new marble countertops along with instructions on how to apply.

So yes, untreated, unsealed concrete will certainly stain. But what about sealed concrete? The short story is, it’s unlikely but there still exists the possibility. The reason is that with all the different sealers available for concrete, there doesn’t exist one perfect sealer for concrete.

Designer concrete producers around the country hold their collective breath when they get calls from past clients, praying that it isn’t a compromised sealer issue they are calling about. They experience this feeling in their gut that’s the equivalent to the way you feel when you’ve just been caught lying. There is always a trade off when choosing a sealer product for concrete, ALWAYS. Here’s what I mean:

I use two different sealers, both offered by Buddy Rhodes Concrete Products. One of them I have used for almost 7 years now. The other I just added to the repertoire. The sealer I have used for years is called ICT, I have no idea what ICT stands for. It offers excellent stain resistance and acid resistance. But you can’t get a truly matte finish with this sealer because the way it works. I can make it satin, but not matte. This sealer basically gets down into the pores of the concrete and chemically reacts with the concrete, and grows a microcrystalline structure, filling the pores with what is essentially glass.

You might think, ‘Wow, that must make it really impenetrable,’ to which I would reply, ‘Slow down a minute.’ Leave a sweaty glass of water on the surface of the concrete for 20 minutes and you’ll see dark ring on the surface. But just because it looks like it seeped into the pores, doesn’t make it so. After a few minutes, that darkness will go away. I promise, I see it happen on my own countertops five times a day. This darkening freaks people out and they call wanting my head on a stake, then I recommend that they wait a few minutes and call me back if it hasn’t gone away. I rarely hear back.

There have been exactly two instances in the last seven years where a client has called me about a stain on ICT sealed concrete. I scratched my head over both, then come to find out that after a little more time, it simply works itself out. Magically, the stain just goes away.

I have no explanation other than Gore-Tex. Just like your rain jacket, this sealer is a breathable technology. It keeps water out, but allows moisture vapor to pass through. This means that your concrete surface is always able to breath. So you can see, there are benefits (good stain- and acid-resistance, self-healing, and breathable) and draw back (no matte finish, darkening when subject to prolonged moisture exposure) to this sealer.

The new sealer I started using is RPS, which stands for Reactive Polyurethane Sealer. It has the sexiest matte finish you can find, but I’ve found that, since it is a plastic (polyurethane) coating, it can scratch and burnish easily.

The urethane coating makes it virtually impossible to stain, and this sealer is also very acid-resistant. The scratches rarely equate to compromised stain protection, but you will have a scratch on the surface, which can be sanded out without a problem (unless you count that I have to come back out to sand the surface and my current lead time is about 4 weeks).

Other Concrete sealers exist. Some are epoxies, which offer terrible acid-resistance but look really nice when applied well. Others are urethane based products which are terrible to apply, if you don’t stop at just the right time you can get snake-skin blotches in the finish. There are acrylic products, which do pretty well, but have become notorious for delaminating.

So you see, just like wood finishes, there are a tremendous variety out there from which to choose. Remember, thoughtful consideration should always be given to what type of use the project will see before selecting the right product.